For years, SCADA systems quietly kept the industrial world running. They’re the hidden force behind power grids, water treatment plants, factories basically, anywhere you need tight control and constant monitoring. Traditional SCADA runs on rules, is reactive but heavily dependent on human oversight.

However, things are shifting fast. AI isn’t just some experimental concept for automation anymore; it’s moving right into the heart of modern SCADA. These systems aren’t just sitting there watching; they’re learning, making predictions, and adapting rapidly. With AI on board, industries are handling issues and equipment smarter while reacting to risks before anything gets out of hand.

This article dives into how AI fits into SCADA, where it’s making the biggest impact, and why this shift matters for the future of industrial control.

Understanding SCADA Systems

SCADA (Supervisory Control and Data Acquisition) systems gather real-time data from all industrial sites and processes. It gives operators a centralized system to monitor and control everything. The system relies on sensors, PLCs (Programmable Logic Controllers), RTUs (Remote Terminal Units), HMIs, and control servers to get the job done. These components form the backbone of IIoT (Industrial IoT) infrastructure.

Traditional SCADA systems excel at visibility and control, but they have limitations. They typically operate on predefined thresholds, follow static rules, and depend on manual effort to interpret alarms or alerts. As industrial environments continue to grow more complex and data-heavy, these limitations become more visible and evident. This is where AI enters the picture.

Why AI Integration Became Necessary in SCADA

Industrial systems generate large volumes of data every second from IoT sensors and connected devices, such as temperature readings, pressure values, vibration patterns, and voltage fluctuations. No human operators or old rule-based systems can process all that information in real time.

That’s where AI steps in to bridge the gap. Instead of sticking to rigid instructions like “Did this number go over the limit?”, AI digs deeper. It asks: Does this look normal? Is something about to go wrong? Is this pattern suspicious, or inefficient?

Nobody wants unexpected downtime, safety issues, or high operational costs. This is why more industries are weaving AI into their SCADA systems. The need for faster decisions and fewer breakdowns is fueling the integration of AI into SCADA environments.

Key Areas Where AI Has Been Integrated into SCADA Systems

SCADA isn’t going to be replaced. Instead, AI only makes it smarter by adding intelligence on top of traditional control frameworks.

Predictive Maintenance and Asset Health Monitoring

One of the biggest gamechangers is predictive maintenance. Instead of waiting for a breakdown or following some fixed schedule, AI models dig through large volumes of past and real-time data, picking up warning signs that slip right past people such as minor vibration in a motor, a sudden temperature shift in a transformer, or a pressure sensors blip in a pipeline. When AI flags something off, maintenance teams can jump in and fix it before anything actually goes wrong. It reduces downtime while extending equipment life. Predictive maintenance is where AI in SCADA really proves its worth.

Smart Anomaly Detection

Traditional SCADA alarms are usually noisy. Operators drown in alerts, most of them are meaningless or low priority. AI cuts through the noise by figuring out what “normal” looks like for each system; then it only raises the flag when something truly odd happens.

Machine learning models track how systems behave over time. If something unusual happens even if it doesn’t break any preset rule; AI detects it. That means fewer but more relevant alerts, and less alarm fatigue for operators. This helps in improving response quality and productivity.

AI-Driven Process Optimization

AI is also changing how SCADA handles process optimization. Instead of just keeping everything at a set value, AI is always tweaking—automatically adjusting controls to boost efficiency and hit quality targets. In the manufacturing industry, it can optimize production while cutting energy use. In power grids, it balances loads better. In water treatment plants, AI can adjust chemical doses as per the quality of water. AI-enabled SCADA is transforming from a control system to helping teams make smarter data-driven decisions that can greatly improve the operations of the industry.

Advanced Forecasting and Demand Prediction

Forecasting is another area where AI-enabled SCADA is important. AI models analyze past data, monitor environmental factors, and identify operational trends to accurately predict future demands, production results, and faults in equipment. Utilities use this to predict peak energy demands and keep the grid steady. This is especially helpful as it helps manufacturers make strategic plans for production and optimize resource use. Better forecasting means fewer surprises and smarter strategic planning across all operations.

Cybersecurity and Threat Detection

With SCADA systems increasingly connected with IT networks and cloud platforms; the risk of cyberattacks is also rising. AI is taking on a bigger role in securing SCADA systems. It monitors network traffic and system behavior, looking for signs of hacking or manipulation. Compared to traditional security tools that only capture known threats, AI can spot any new or unusual activity that may indicate a possible insider threat, malware activities, or unauthorized access. This layer of protection is crucial for critical infrastructure where cyberattacks can have severe consequences.

In short, AI isn’t here to replace SCADA. It’s here to make it sharper, faster, and more resilient.

How AI Is Technically Integrated into SCADA

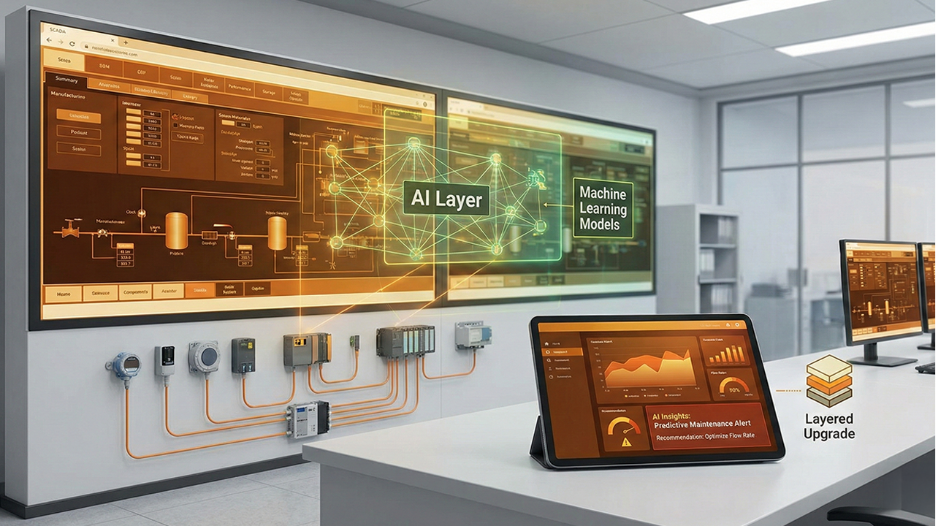

There's no need to rip out your existing SCADA system to add AI. Most of the time, you can just layer AI on top of your current architecture. SCADA sensors keep collecting data like usual, and that data flows straight into machine learning models running on edge devices, local servers, or cloud platforms. The AI processes this data and generates insights, predictions, or recommendations then sends them back to operators through dashboards, alerts, or decision-support tools.

This “layered” setup allows companies to upgrade step by step while maintaining reliability and control.

Benefits of AI-Enabled SCADA Systems

Predictive Maintenance

AI identifies early warning signs of equipment failure by analyzing patterns in sensor data. This allows maintenance teams to take immediate action to fix the issue before breakdowns occur. This significantly reduces the downtime and helps machines last longer.

Lower Operational Costs

AI helps in optimizing processes and capturing early signs of failures before they blow out of proportion. This significantly reduces time spent on maintenance, cuts energy waste, and prevents production losses.

Faster and Smarter Decision-Making

There is no need for operators to depend on fixed thresholds anymore. After AI analyzes real-time and historical data, it produces meaningful and actionable insights to enable data-driven decision-making processes even under dynamic conditions.

Better Alarm Management

Instead of drowning operators in a sea of pointless alerts, AI filters the noise and flags only critical anomalies. This results in less alarm fatigue while facilitating quicker and more accurate responses.

Improved Process Efficiency

AI constantly adjusts operational settings to make sure everything runs as smoothly as possible. This results in higher quality output and allows smarter use of resources.

Enhanced System Reliability

AI picks up unusual behavior or performance degradation in early stages, making the whole system more stable and cutting down on the risk of cascading failures.

Challenges and Considerations in AI-SCADA Integration

Data Quality and Availability

AI models rely heavily on accurate, consistent, and up-to-date data. Incomplete, noisy, or poorly calibrated sensor data can lead to predictions that are unreliable and produce poor insights.

Complex System Integration

Integration of AI with traditional or old SCADA infrastructure can pose a significant technical challenge and may require upgrades in systems or additional middleware.

Lack of Skilled Expertise

Successfully integrating AI into SCADA systems requires collaboration between control engineers, data scientists, and IT teams. Many organizations lack this internally, which leads to technical problems.

Trust and Explainability Issues

Some operators may feel skeptical to rely on AI recommendations is the system fails to give clear explanation of how conclusions are drawn, especially in safety-critical situations.

Cybersecurity Concerns

With increasing connectivity and data exchange, risks of cyberthreats are also rising. Therefore, adopting strong cybersecurity controls measures is essential for proper functioning of AI-enabled SCADA systems.

Initial Investment Costs

Initially, implementing AI solutions may require some upfront investments in infrastructure, training, and systems to redesign for successful and smooth integration.

The Future of AI in SCADA Systems

AI-enabled SCADA systems are still evolving. There are a lot of expectations from future systems. They are expected to be equipped with greater autonomy and AI that not only recommends actions but also execute controlled adjustments under pre-defined rules.

Edge AI will play a significant role in the near future, enabling real-time intelligence closer to the process. Digital twins combined with AI will allow operators to simulate scenarios before applying real changes. With AI acting as a co-pilot, the collaboration between humans and machines will be deepened. As industries continue to digitalize, AI-enabled SCADA systems will become an industry standard rather than an exception.

Final Thoughts

The integration of AI into SCADA systems marks a fundamental shift in industrial automation. Earlier, SCADA was just a system to monitor and control industrial operations but now it is becoming a platform for intelligence, smarter prediction, and optimization. AI is not meant to replace human expertise or conventional control logic. Rather, its purpose is to further enhance them for improved productivity. AI turns raw or unfiltered data into meaningful and actionable insights. Those insights then help make better informed decisions.

Those industries who are looking for higher reliability, efficiency, and resilience must integrate AI into SCADA systems as it is no longer a future concept; but an emerging necessity.