Logistics is an important function for any business that is involved in manufacturing or distributing the products. The management of the flow of products, data, and services between a company and its suppliers, warehouses, and clients is the fundamental definition of logistics.

In order to get their products to market quickly and affordably, businesses need to have a strong logistics plan. Logistics involves two major flows: inbound logistics and outbound logistics. Optimizing the supply chain requires an understanding of the variations between the two.

Inbound Logistics

Inbound logistics refers to the transport, storage, and delivery of goods coming into a business. It covers the handling of components or raw materials from suppliers to manufacturing or assembly facilities.

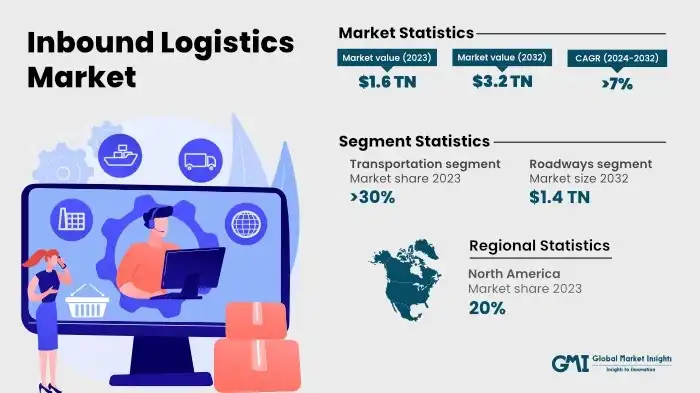

Inbound Logistics Market was valued at USD 1.68 trillion in 2023, and it is expected to grow at a CAGR of more than 7% between 2024 and 2032.

Key Activities of Inbound Logistics

- Procurement of materials and parts from suppliers

- Transportation of inbound goods via ships, planes, trains, and trucks

- Receiving and inspection of incoming items

- Storage of inbound inventory in warehouses and stockrooms

- Materials handling of inbound goods with equipment like forklifts

- Inventory control and management of raw materials and components

Inbound logistics focuses on ensuring components used for production or finished goods for resale arrive at their required destinations in good condition, on time, in the correct quantities, and at a good price.

The inbound supply chain commences when an order is placed with a supplier and ends when goods arrive at production facilities or warehouses. Managing inbound freight can be quite complex for companies with global supply chains spanning numerous suppliers, production sites, and countries. These and many other problems can now be solved by creating the necessary software:https://www.eliftech.com/logistics/.

Goals of Inbound Logistics

The main priorities for inbound logistics include:

Cost efficiency - Controlling freight and warehousing expenses related to ordering, transporting, handling, and storing inbound goods. Using economies of scale through consolidated orders.

Inventory optimization - Ensuring optimal stock levels by having components and materials available as needed for production but avoiding excessive inventory carrying costs. Using just-in-time methods can improve this.

Quality - Preventing damage, defects, or delays with inbound shipments to avoid production slowdowns or shutdowns. Inspection processes help monitor quality levels.

Speed - Quickly moving inbound inventory from suppliers to where it is required for transformation activities. Efficient transportation modes and routes support velocity.

Visibility - Tracking the location and status of inbound orders at all stages to address issues promptly. Inventory management software provides visibility.

Supplier integration - Closely partnering with suppliers on pricing, transport, packaging, and other specifications aids coordination.

Working with a trusted China sourcing agent can optimize both inbound and outbound logistics for global businesses. Their expertise ensures smoother procurement, timely delivery, and improved supply chain efficiency.

Outbound Logistics

Outbound logistics involves transporting, storing, and distributing finished products and goods to customers or downstream supply chain partners like wholesalers or retailers. It comprises the processes for finished goods flows from the end of the production line to the end user.

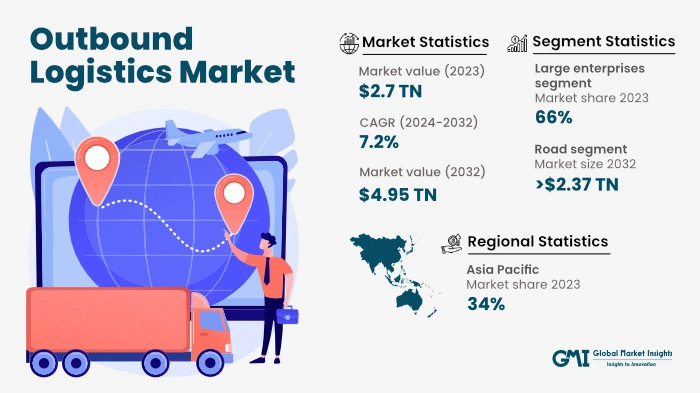

The outbound logistics market was valued at USD 2.7 trillion in 2023, and it is expected to grow at a CAGR of 7.2% between 2024 and 2032. The rise of online shopping and e-commerce booms around the world drives market growth.

Key Activities of Outbound Logistics

- Order processing and confirmation for customer orders

- Warehousing and inventory control of finished goods

- Materials handling of outbound products with equipment like conveyors and forklifts

- Packaging of finished products to support shipping

- Transportation of outbound goods via container ships, planes, trains, trucks to customers

- Installation or final assembly at customer sites in some cases

While inbound logistics focuses on sourcing, production, and plant warehouses, outbound logistics emphasizes the distribution side involving finished goods forwarded to resellers or end-use customers in the right volumes, at the right time, and in good condition.

Priorities including speed, flexibility, and cost must be balanced while managing worldwide export operations with a large client base, erratic demand, and complicated logistics.

Goals of Outbound Logistics

The key goals associated with outbound logistics management typically include:

Customer service - Meeting customer-requested delivery dates and quantities and providing excellent service overall.

Cost efficiency - Controlling distribution and delivery expenses while maintaining acceptable service levels. Leveraging distribution centers and scale transportation modes can reduce costs.

Asset optimization - Rightsizing inventory, warehousing, and transportation capacity to demand so assets are not over or underutilized. Cross-docking improves utilization.

Speed & reliability - Quickly fulfilling and delivering customer orders when promised without shortages, damage, or delays. Strategic distribution center locations support speed.

Visibility - Tracking orders and inventory at all points within the outbound supply chain to quickly address issues. Integrated IT systems enable visibility.

Collaboration - Partnering with downstream supply chain members on planning, sales forecasts, promotions, and inventory data facilitates collaboration.

Key Differences Between Inbound and Outbound Logistics

While inbound and outbound logistics have some overlapping supply chain activities like transportation and warehousing, there are important differences between the two concepts:

Ownership

Inbound logistics focuses on purchasing and sourcing materials that suppliers still own before receipt. Outbound logistics centers on distributing and delivering finished goods owned by the shipper.

Order Direction

Inbound logistics brings materials and components from multiple suppliers into centralized manufacturing or assembly plants. Outbound logistics ships orders in a dispersed way from plants to many resellers and end customers.

Inventory Focus

Inbound logistics emphasizes managing the sourcing, quantities, timing, and storage of raw materials and component inventory. Outbound logistics concentrates on finished goods inventory availability, order cycle times, and distribution velocity.

Direction of Funds

Inbound logistics involves paying suppliers for procured items, while outbound logistics collects payments from customers on delivered orders. One pays while the other gets paid.

Degree of Control

Companies often have more control over outbound distribution since it involves their assets, while inbound relies more on external supplier processes. However, strategic sourcing partnerships are helping improve inbound control.

Key Performance Indicators

Key metrics for inbound logistics include supplier lead time, supply quality levels, landed costs, and inventory turns or days on hand. Outbound logistics focuses on customer-perfect order performance, fill rates, distribution costs per unit, and cash-to-cycle times.

Technology Enablement

Inbound vs outbound shipping leverages supply chain execution systems for functions like procurement, warehouse management, and manufacturing execution. Outbound logistics relies on order management, inventory optimization, transportation management and omnichannel commerce systems.

Let’s explore inbound and outbound logistics activities further.

Key Inbound Logistics Activities

Key operations related to planning, sourcing, shipping, warehousing, inventory management, and material handling are included in inbound logistics.

Sourcing and Procurement

A systematic sourcing and procurement process allows companies to find suppliers, evaluate capabilities, qualify partners, negotiate agreements, place purchase orders, and buy needed components or materials.

In order to make the best purchasing selections possible, strategic sourcing incorporates features of spend analysis, market research, RFPs, and supplier audits. These criteria include price, quality, reliability, technology, location, and sustainability.

Procurement digitization through e-procurement software, electronic data interchange, and supply chain control towers is streamlining interactions with suppliers to ease inbound parts replenishment.

Inbound Transportation Management

Transporting raw materials, parts, and components from diverse domestic and global suppliers to manufacturing plants and warehouses relies on all modes of transportation, including ocean shipping containers, planes, freight trains, and delivery trucks.

Inbound logistics management optimizes routing, consolidates volumes across suppliers to improve cost efficiency, coordinates timing with production schedules, and provides shipment visibility.

Inbound Warehouse Management

Warehouses store and manage sourced parts inventory close to production areas to enable flexible, just-in-time material availability for assembly processes.

Inbound warehouse management handles putaway, locating, picking, and inventory tracking of thousands of material types from various vendors using an inbound logistics system for organization, storage optimization, and inventory controls.

Inventory Control and Planning

Balancing inbound supply with production demand requires careful inventory planning and optimization, especially with extended global supply chains. Inventory inbound logistics management tools like MRP help coordinate purchasing, production schedules, and stocking levels across extended supply networks.

RFID tags track and make component inventory visible, and machine learning and advanced analytics help forecast material demand more accurately.

Inbound Quality Inspection and Supplier Management

To ensure that purchased items meet specifications, the inbound quality processes include evaluation of material condition, quantity, size and defects through the receiving inspection.

In order to encourage suppliers to deliver goods and services on schedule, with high quality, promptness, and sustainability, suppliers might use supplier scorecards. Through supplier development initiatives, competencies are improved and opportunities are identified through analytics.

This highlights some of the key areas of managing inbound logistics flows for a better flow of operations.

It is time to proceed with the discussion of the key aspects of outbound logistics.

Key Outbound Logistics Activities

Outbound logistics focuses on order processing, finished goods warehousing, packaging, transportation, installation, and reverse logistics requirements occurring after the production process.

Order Management

Customer orders arrive through multiple sales channels, including ecommerce websites, electronic data interchange with major retailers, phone, fax, email, EDI, and electronic store ordering by resellers.

With features including order validation, inventory availability checks, shipment date promises, order status updates, and invoices, outbound order management coordinates requests across channels.

Outbound Warehouse Management

Finished goods warehousing provides buffer inventory to fulfill customer orders rapidly. Activities here include finished goods receipt, putaway, replenishment, picking, packing, staging near shipping docks, and inventory level monitoring.

Warehouse management and control systems optimize space, layouts, inventory slotting, resources, and material flows to meet order requirements efficiently.

Packaging, Loading & Shipping

Goods are packed in protective casings with wrapping, insulation, and pallets where necessary to prevent damage in transit. Protection, preservation, sustainability, and maximum marketing are all objectives of packaging, and a strong packaging design solutions approach ensures that these objectives are met efficiently.

Transporting finished products into containers, trucks, railcars, planes, or ships in warehouses, distribution centers, or intermodal facilities use material handling equipment such as forklifts, conveyors, cranes, scanners, and automated guided vehicles.

Transportation Management

Outbound transportation management includes mode choices, carrier sourcing, route determination, freight cost assessment, shipment aggregation, cargo monitoring, and delivery arrangement.

Optimizing transportation economics while meeting customer timeframes is a balancing act aided by analytics.

Installation, Service & Reverse Logistics

Some products require installation or field service to start up equipment delivered to customer sites. Organizing technicians, managing spare parts, and setting up visits all contribute to a better client experience.

Reverse logistics handles product returns, recalls, repairs, refurbishment, resale, recycling, and waste disposal across a closed-loop supply chain. For this to happen, inbound and outgoing flows must be coordinated.

Conclusion

While inbound logistics and outbound logistics have some distinct differences in ownership, flow direction, performance metrics, and areas of control, connecting them through aligned priorities, synchronized plans, shared data, and collaborative relationships generates optimal end-to-end supply chain results.

As logistics challenges grow across expanding global networks, sophisticated transportation management, warehouse management, and supply chain control systems enable the inbound and outbound sides to interoperate as a unified ecosystem.

Companies that bridge their inbound and outbound logistics flows through robust integration and alignment position themselves to respond to customer needs and market changes with agility, efficiency and competitive advantage. Managing the critical linkage between procurement and distribution remains an imperative for supply chain excellence now and into the future.